Our Capabilities

professional metal fabrication, processing, and panel solutions powered by advanced technology and decades of expertise in ct.

Metal Fabrication

We deliver custom metal fabrication solutions, including welding, folding, shearing, and custom profiles for architectural applications. With advanced technology and expert craftsmanship, ASF ensures precision, durability, and fast turnaround on every project.

Panel Fabrication

We specialize in custom fabrication of ACM, fiber cement, roof, and wall panels to meet architectural design and performance standards. ASF delivers precise, high-quality panels using top materials and advanced technology for lasting results.

Metal Processing

ASF offers precision metal processing services, including CNC routing, laser cutting, punching, and in-house coil handling. Our advanced equipment ensures accurate, efficient processing for architectural and custom fabrication projects.

Painting

ASF offers post-painting services, including both liquid and powder coating, to enhance the durability and appearance of metal components. We provide a wide range of color and finish options to meet specifications and protect against wear and corrosion.

Drafting

ASF provides professional drafting services to turn your concepts and ideas into precise fabrication-ready drawings. Our team collaborates closely with clients to ensure every detail meets architectural standards and project specifications.

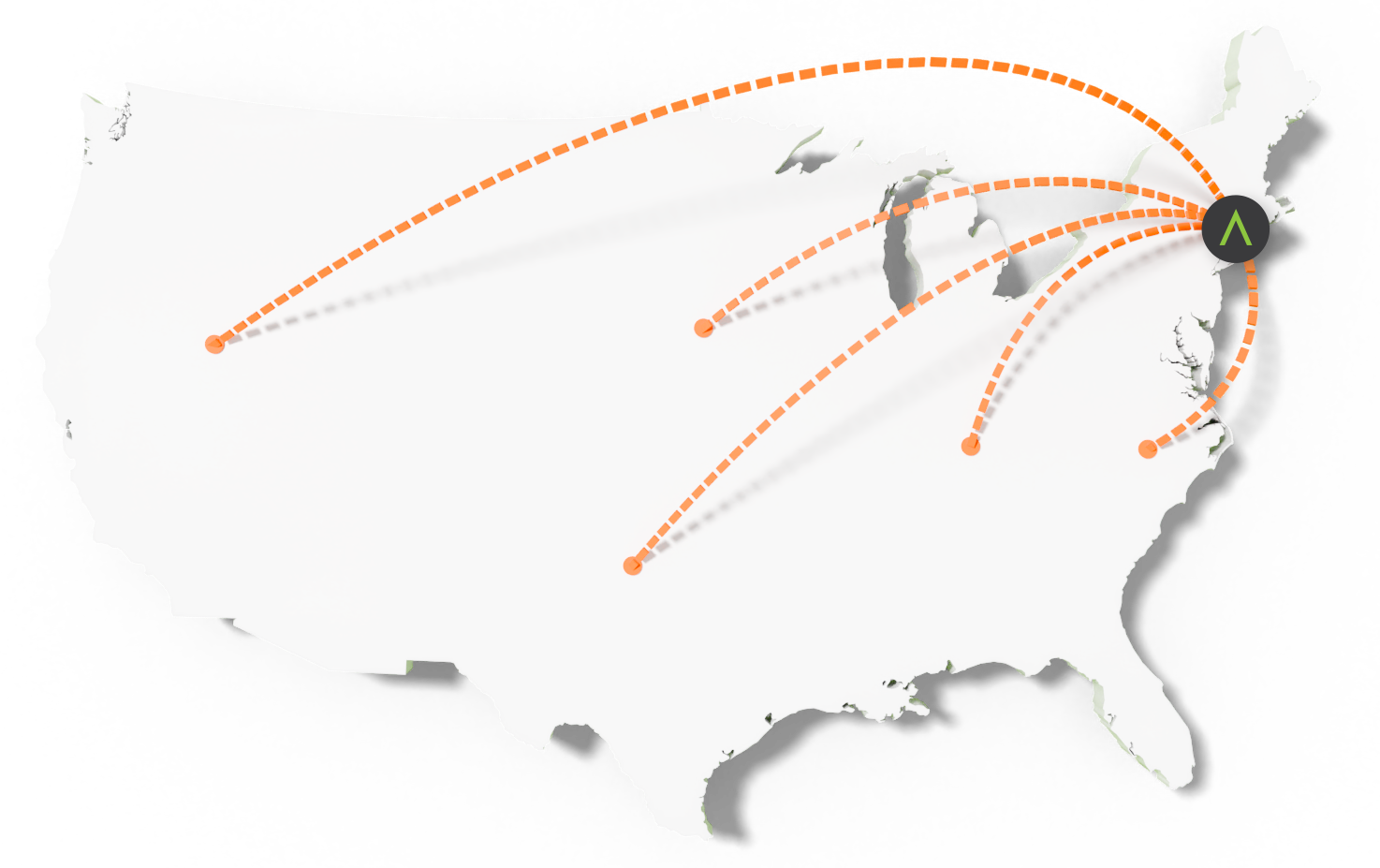

Reliable Shipping Across the Continental U.S.

No matter where your job site is located, we can get your order there—fast and securely. Every shipment is carefully crated to protect your materials in transit and ensure they arrive in perfect condition. We work with trusted freight carriers to keep your timelines on track. From a single pallet to full truckloads, ASF delivers nationwide with confidence.

why choose us

Your trusted partner for advanced metal fabrication.

decades of experience

Extensive industry experience delivering precision and reliability.

Panel Experts

Manufacturing ACM panels, aluminum composites, and custom panel solutions.

Advanced Technology

Equipped with cutting-edge machinery, including CT’s only long-folding machine.

Architectural Focus

Specializing in high-end metal fabrication, not just miscellaneous steel.

frequently asked questions

Do you provide design or drafting assistance as part of your services?

Absolutely. ASF offers drafting and design support to help clients refine their concepts and ensure they are fabrication-ready. Whether you have detailed plans or just an idea, we’ll work with you to create accurate, production-ready drawings.

Lorem ipsum dolor sit amet, consectetur adipiscing elit?

We work with a wide range of metals, including aluminum, aluminum composite material (ACM), copper, stainless steel, zinc, mild steel, and high-density fiber cement. Our extensive material selection allows us to provide durable, high-quality solutions for various architectural and construction applications.

Lorem ipsum dolor sit amet, consectetur adipiscing elit?

Describe the item or answer the question so that site visitors who are interested get more information. You can emphasize this text with bullets, italics or bold, and add links.Lorem ipsum dolor sit amet, consectetur adipiscing elit?

Describe the item or answer the question so that site visitors who are interested get more information. You can emphasize this text with bullets, italics or bold, and add links.

What materials can ASF work with across its capabilities?

We specialize in working with a wide variety of materials, including aluminum, stainless steel, mild steel, copper, zinc, ACM panels, fiber cement panels, and phenolic panels. Our in-house processing and fabrication capabilities ensure precise handling of each material to meet architectural and structural standards.

Can ASF handle nationwide projects?

Yes, while we are based in Connecticut, ASF serves clients nationwide. Our capabilities are designed to support both local and large-scale projects across the U.S., with reliable shipping and delivery options to keep your project on schedule.