Our Materials

Premium metals and materials designed for durable, precise, and high-quality architectural fabrication.

aluminum

Lightweight, durable, and corrosion-resistant, aluminum is ideal for a wide range of architectural applications. Its versatility makes it perfect for custom fabrication, from panels to decorative elements. We provide high-quality aluminum in various gauges to meet the demands of both structural and aesthetic projects. Our advanced machinery ensures precise forming and cutting for even the most detailed aluminum designs.

Aluminum Composite Material

ACM panels combine strength and flexibility, offering a sleek, modern finish for exterior and interior architectural designs. They are perfect for cladding, signage, and facades due to their durability and lightweight structure. ASF fabricates ACM panels to precise specifications using top brands like ALPOLIC and ALUCOBOND. With a variety of colors and finishes available, ACM panels deliver both performance and visual impact for any project.

Copper

Copper is renowned for its timeless appearance, natural corrosion resistance, and long-lasting performance. It develops a distinctive patina over time, adding character to architectural designs. Ideal for roofing, gutters, and decorative elements, copper offers both beauty and functionality. ASF provides precision-fabricated copper components tailored to meet unique project requirements.

High-Density Fiber Cement

High-density fiber cement panels offer durability, weather resistance, and low maintenance for modern architectural applications. Perfect for facades and wall cladding, they provide a sleek, contemporary look while standing up to harsh environments. ASF fabricates fiber cement panels, such as EQUITONE, to exact specifications for seamless installation. Available in a variety of textures and finishes, these panels combine performance with aesthetic versatility.

Mild Steel

Mild steel is a versatile and cost-effective material commonly used in structural and architectural metalwork. Known for its strength and ease of fabrication, it’s ideal for custom components, framing, and support systems. ASF offers high-quality mild steel processing, including cutting, forming, and welding services. With precise craftsmanship, we ensure every mild steel element meets project specifications and industry standards.

Phenolic

Phenolic panels are durable, moisture-resistant, and perfect for high-traffic exterior and interior applications. Often used in ventilated facades and decorative cladding, they offer excellent color stability and impact resistance. ASF specializes in CNC routing and fabrication of phenolic materials to deliver clean, accurate finishes. These panels provide a modern aesthetic while ensuring long-term performance in demanding environments.

Stainless Steel

Stainless steel is valued for its corrosion resistance, strength, and clean, modern appearance. It's an excellent choice for architectural features, wall panels, trim, and custom metalwork exposed to the elements. ASF fabricates stainless steel in various gauges, ensuring precision for both functional and decorative applications. With its durability and sleek finish, stainless steel enhances both the longevity and look of any project.

Zinc

Zinc is a premium architectural metal known for its self-healing properties and ability to form a protective patina over time. It’s widely used for roofing, wall cladding, and custom profiles due to its flexibility and long lifespan. ASF provides expertly fabricated zinc components, offering both aesthetic elegance and environmental sustainability. Available in multiple finishes, zinc delivers a refined, modern look that evolves beautifully with age.

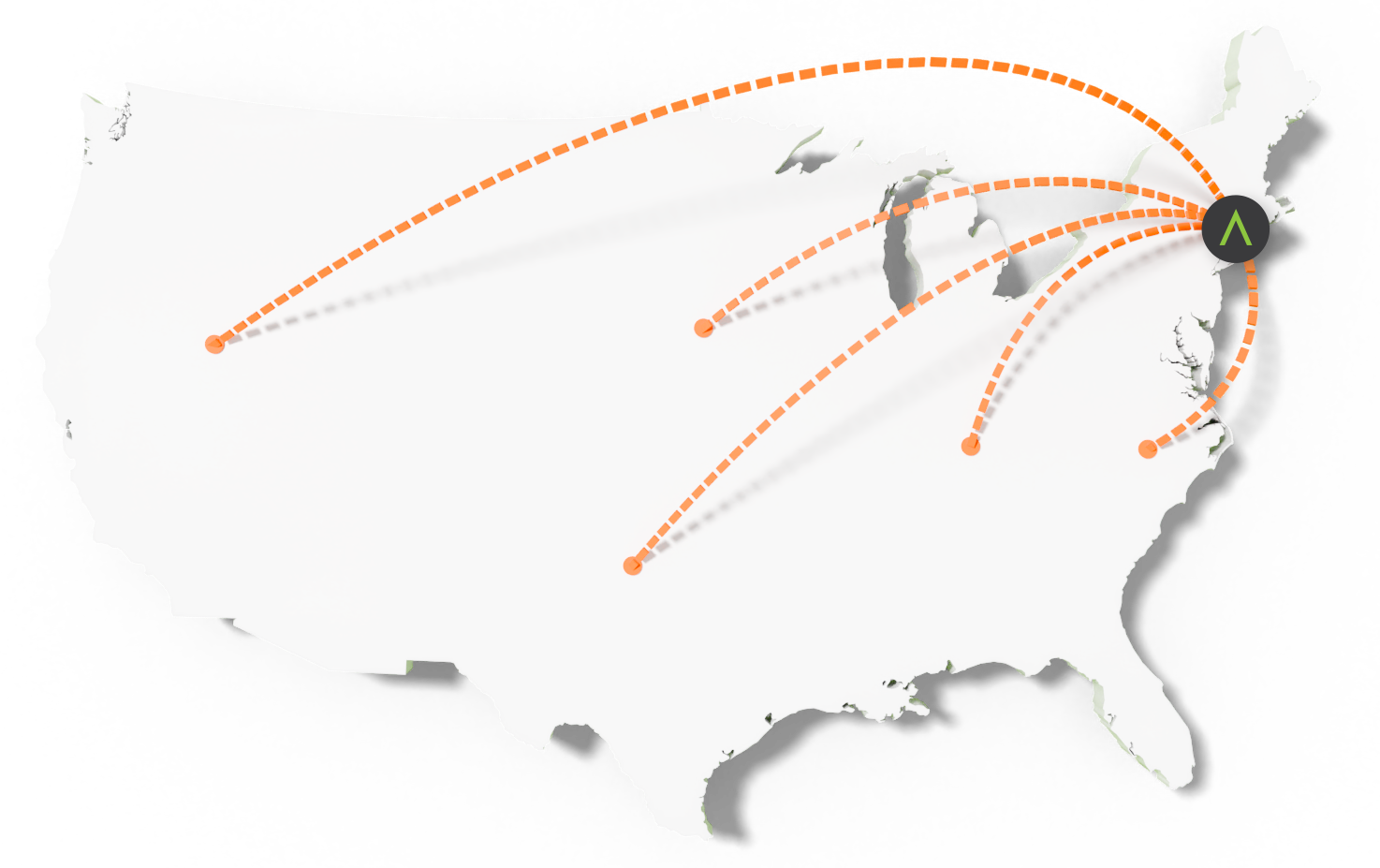

Reliable Shipping Across the Continental U.S.

No matter where your job site is located, we can get your order there—fast and securely. Every shipment is carefully crated to protect your materials in transit and ensure they arrive in perfect condition. We work with trusted freight carriers to keep your timelines on track. From a single pallet to full truckloads, ASF delivers nationwide with confidence.

why choose us

Your trusted partner for advanced metal fabrication.

decades of experience

Extensive industry experience delivering precision and reliability.

Panel Experts

Manufacturing ACM panels, aluminum composites, and custom panel solutions.

Advanced Technology

Equipped with cutting-edge machinery, including CT’s only long-folding machine.

Architectural Focus

Specializing in high-end metal fabrication, not just miscellaneous steel.

frequently asked questions

Can ASF fabricate custom components using supplied materials?

Yes, we can work with customer-supplied materials as long as they meet fabrication requirements. Our team will review the material specifications to ensure compatibility with our machinery and processes before starting production.

Do you provide guidance on selecting the right material for my project?

Absolutely. ASF offers consultation services to help you choose the best material based on your project’s design, durability needs, budget, and environmental conditions. We’ll ensure you get a solution that balances performance and aesthetics.

What are the lead times for material fabrication and delivery?

Lead times vary depending on the material type, project complexity, and current production schedule. However, ASF is known for quick turnaround times, and we always strive to meet tight deadlines without compromising quality. Contact us directly for a personalized estimate.